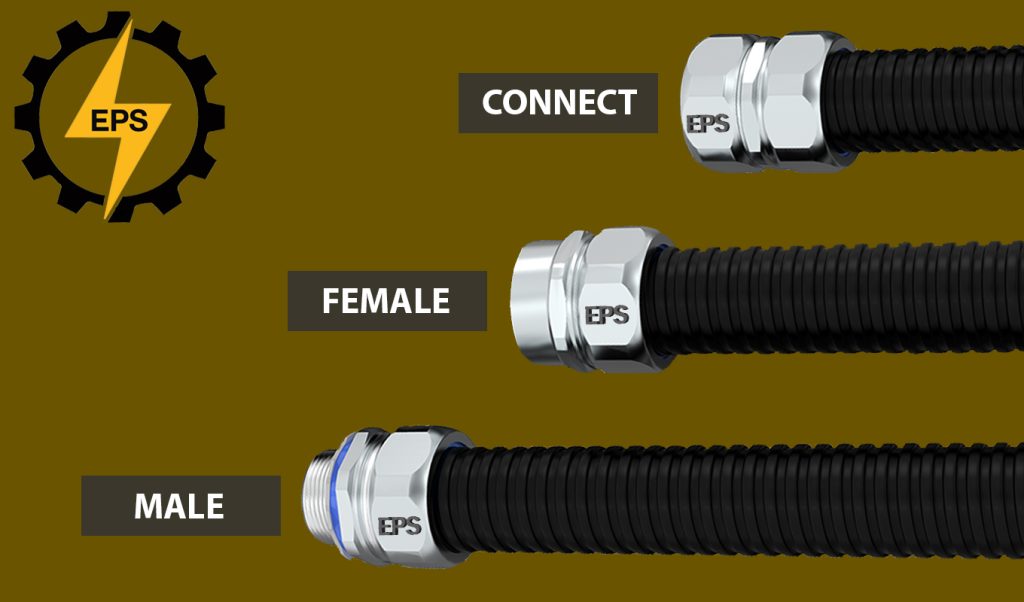

Sealed Flexible Conduit Connector

- High sealing level preventing moisture and dust ingress

- Corrosion and chemical resistance (galvanized coating)

- Suitable for industrial (Safe) and non-industrial environments

- Higher price

- Easy installation

- Impact resistant (secure fixation)

- Resistant to conduit pull-out (has a grip insert preventing conduit from slipping out)