We all know that the use of cables and wires for construction and construction projects is of special importance. We also know how important it is to protect them against corrosion, moisture and serious damage. For this purpose, special tools should be used.

One of the things that can be used to protect cables and wires in projects is the flexible tubes or the so-called flexi tube. Now, you may have this question, what exactly is a flexible pipe and what is its use?

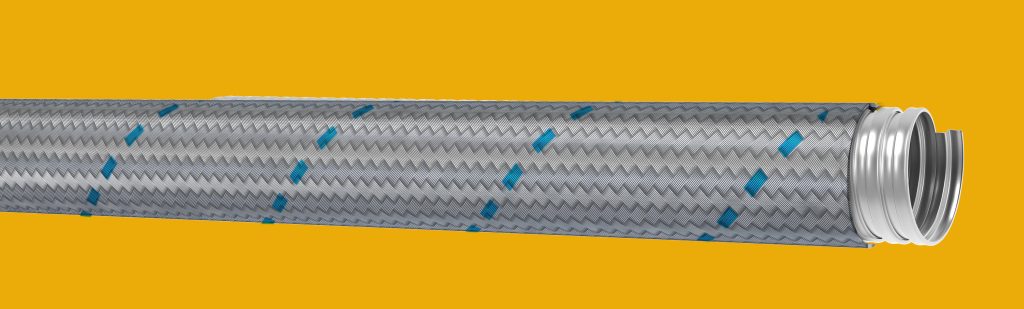

Flexible is a flexible metal hose pipe that is produced with the purpose of protecting all types of wires and cables in electrical installations, especially installations exposed to moisture and dust. Another name for flexi pipe is metal hose pipe.

The flexi pipe consists of three layers, the outer and inner layers are made of laminated aluminum and the middle layer is made of polyethylene insulation.

The structure of this type of flexi pipe is in the form of metal strips that are cicular, but with a square cross-section, and are covered with PVC coating at the end. Its raw materials are made of galvanized sheets like many devices in the electrical industry.

Of course, these galvanized sheets have a PVC coating that adds self-extinguishing properties to it. Also, this coating makes the pipe resistant to light, heat and ultraviolet rays. Other advantages of this cover can be mentioned, protecting the metal hose pipe and the threads passed from inside it against moisture, water and chemicals.

Therefore, coated flexible is mostly used in open, wet spaces or areas where the cable is to be installed underground.

As the name suggests, this type of pipe does not have PVC coating. For this reason, their resistance to external damage is reduced compared to the coated flexible pipe. Therefore, their use is mostly in indoor environments.

This type of flexi pipe is made of metal and shielded and is mainly used for telecommunication wiring inside the closed space to be an insulator to prevent the penetration of magnetic waves.

In addition to the shield, this tube model has a coating of material. It is plastic and is mostly used for outdoor telecommunication wiring because in addition to preventing the penetration of magnetic waves, it is also resistant to moisture, water, chemicals, etc and… like a coated flexible pipe.

From flexi pipe or in other words, whip pipe, in various industrial and construction dimensions, including lighting systems, optical fiber and protection of all kinds of wires and cables, false ceilings, CCTV systems, as well as establishing connections between different machines. Industrial and other equipment is used.

This Gland is suitable for connecting metal hose pipe to plastic and metal distribution boxes. The two-screw Gland can be connected directly to the female thread of the workplace after removing the accompanying nut, or installed in the hole in the workplace through the accompanying nut.

The body of these types of Glands are mostly made of aluminum and do not rust in open environments. The screws used in this Gland are mostly iron and are coated with zinc alloy and galvanized.

Single-screw and double-screw Glands have a relatively low safety when connecting, and the possibility of its separation from the flexible pipe is very high when it is stretched. Also, due to not having a sealing part, it cannot be protected from penetration and prevent dirt and moisture.

The most important and practical type of whip pipe fittings metal, Flexible Conduit Connector. In Electro Persian Sepahan company, Flexible Conduit Connectors are produced in 3 models: Male, Female and Connect.

From Male Conduit Flexible Connector is used to connect flexible pipe to Junction box, factory machinery and equipment, cable tray, etc, from Female Conduit Flexible Connector is used to connect whip pipe to steel pipe and conduit, and from Connect Conduit Flexible Connector is used to connect the two ends of the flexible pipe to each other.

Due to the higher strength of the Flexible Gland compared to other Glands and its resistance to rust, it is very widely used. The Flexible Conduit Connector of the EPS production group is made of zamak or aluminum (according to the customer’s request) and with a galvanized, nickel and chrome coating (according to the customer’s order), it is very resistant to rust and corrosion.

Flexible EPS pipe Connector with sealing washers prevents the penetration of moisture, water and dust into the pipe and parts. For this reason, it is used in both open and closed spaces.

For more information, it is recommended to read the Flexible Conduit Connector article.

Due to the special importance of using Flexible pipe in electrical installations and construction and industrial projects, it is very important to choose the type of flexible pipe based on the environment and efficiency as well as its connection type. EPS company experts are at your service to provide free device.

You can use cantact us page to communicate with the experts of Electro Persian Sepahan production group.